全国服务热线:

+86-372-2595077/2595078/2595088

用途:

本系列产品是一种机电转换装置。在额定行程及额定电流范围内,其输出力与输入信号成比例。与比例控制放大器配套使用,可对电液比例阀的阀芯位置进行精确控制。它适用于先导式比例溢流阀、比例减压阀及电液比例复合阀(PQ阀)等多种电液比例阀。具有较高的重复精度和良好的线性增益。

主要技术参数

型号 | GV40-4-A |

额定行程 (mm) | 3 |

全行程 (mm) | 3.2 |

额定电流 (A) | 0.8 |

额定吸力 (N) | 48 |

电阻/20℃ (Ω) | 10 |

力滞环 (%) | ≤2 |

电流滞环 (%) | ≤2 |

通电率 (%) | 100 |

重复精度 (%) | ≤1 |

承受静态油压 (MPa) | 21 |

耐热等级 | F |

* 处参数可根据实际应用订做。

正常工作条件

● 使用环境中应无足以腐蚀金属和破坏绝缘的气体和尘埃。

● 电磁铁适合长期工作制、断续周期工作制。

● 外壳防护等级为IP65。

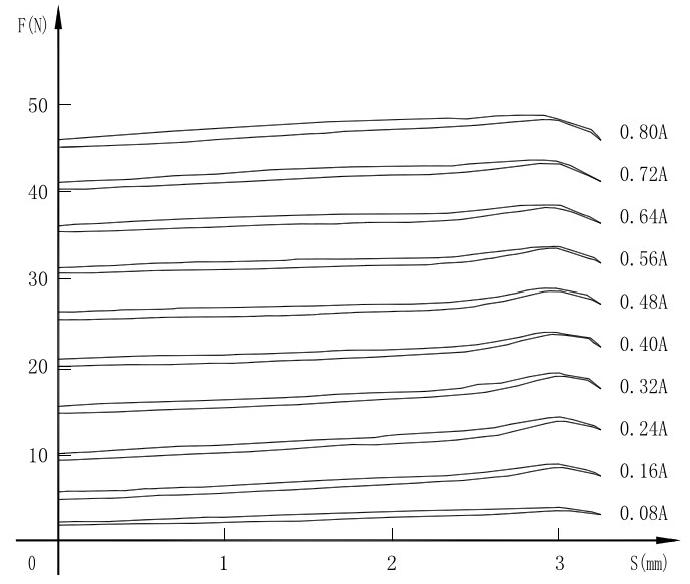

稳态行程-力特性曲线

位移(mm)

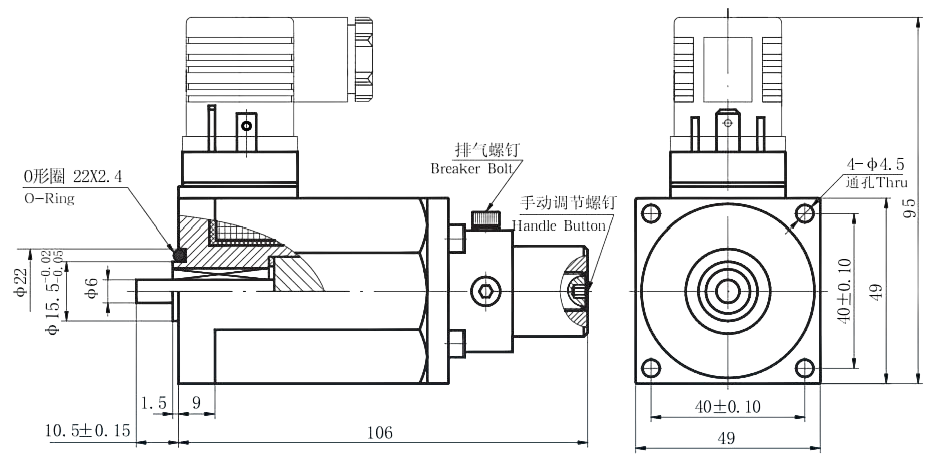

外形及安装尺寸

使用注意事项

● 安装位置

排气孔务必装在上方。

● 排气

为进行稳定的控制,请排净电磁铁内的空气,使电磁铁腔内充满油。

排气时,请缓缓松开电磁铁端部的排气螺钉。注意防止油液喷溅。

● 手动调节螺钉

在初期调整或因电气故障使电磁铁没有输入电流时,可转动手动调节螺钉,临时设定阀的压力或流量。正常使用时请务必 使手动调节螺钉返回原位。

样本说明

● 对超出本样本要求的应用场合,请询问本公司。

● 特性曲线仅供参考。

● 主要特性参数均为实验室条件下获得。本公司保留修改参数的权力。

中文(简体)

中文(简体) English

English Русский

Русский Español

Español